owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Mv Inspection , Electronic Dynamometer , Vehicle Inspection Price , We welcome new and old clients from all walks of lifestyle to speak to us for potential organization relationships and mutual success!

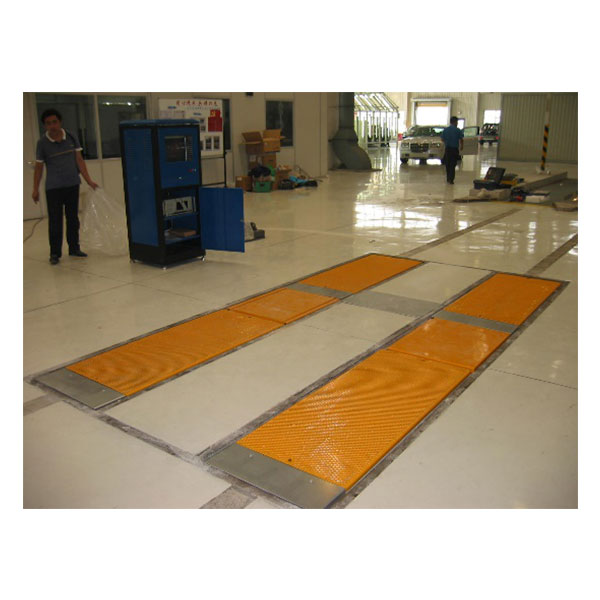

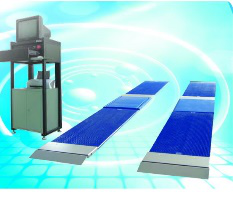

Factory Free sample Chassis Dyno Testing - Platform brake tester – Orient Detail:

Configurations

| Models |

Configuration |

Description |

|

BKW-32,500 (2,500kg/axle)

|

| 4BKWS-3 |

|

Platform brake, weighing, sideslip and suspension tester with 4 main plates, 1 sideslip plate, ldummy, U2 console |

| 2BKWS-3 |

|

Platform brake, weighing, sideslip and suspension tester with 2 main plates, 1 sideslip plate,Idummy, U2 console |

|

BKW-10 (10,000 kg/axle)

|

| 4BKWS-10 |

|

Platform brake, weighing, sideslip and suspension tester with 4 main plates, 1 sideslip plate, ldummy, U2 console |

| 2BKWS-10 |

|

Platform brake, weighing, sideslip and suspension tester with 2 main plates, 1 sideslip plate, ldummy,U2 console |

Model: BKW series

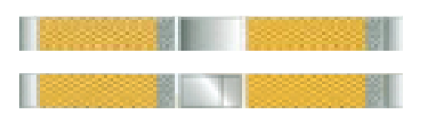

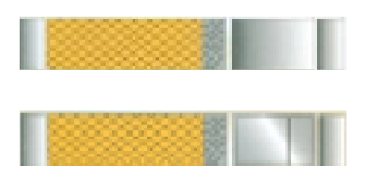

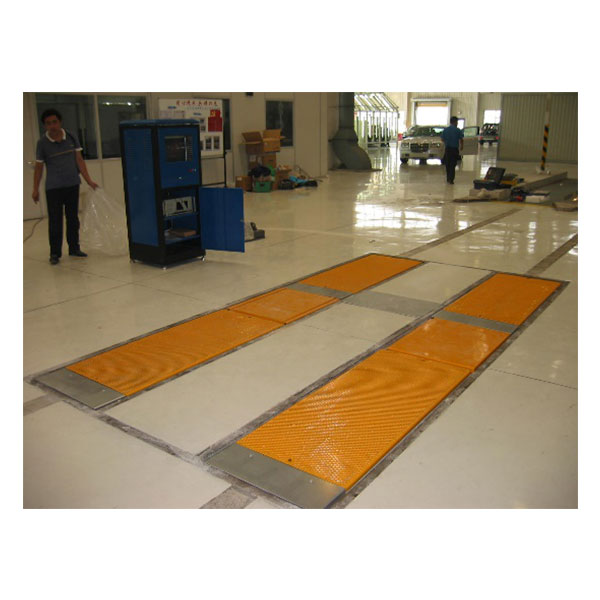

Platform brake tester makes the brake test approach the real brake process on road and reflects the changes in dynamic weight of axle load. It is modulated to combine functions of brake force, sideslip, weighting and suspension.

BKW series is very easy to install, maintain and operate. Its high flexibility enables end user to configure its own tester easily and is well accepted by garages, inspection stations and car manufacturers.

It is not necessary to construct a pit for the equipment.

There is no AC power inside the platform and power consumption is well limited.

Only with one brake action, all results of brake, suspension, dynamic weight and sideslip can get within seconds.

The limited thickness (50/70mm only) and knock down” installation makes easy use on a flat surface anywhere.

All 4 wheels can be tested synchronized.

Summary Results

Brake force per wheel N

Drag force per wheel N

Brake force of hand brake N

Deceleration per axle % or m/s2

Deceleration of whole vehicle % or m/s2

Imbalance per axle %

Suspension performance %

Suspension difference %

Side slip mm/m

Static weight per wheel/axle kg

Dynamic wheel per wheel/axle kg

Inertial center movement graphic

Specifications

| Items |

BKW-3 |

BKW-10 |

| Axle load tested( k)g |

2500 |

10000 |

| Brake force range for each wheel (N) |

10000 |

40000 |

| Side slip test range ( mm/m) |

±10 |

±10 |

| Test speed ( km/h) |

43961 |

43961 |

| Accuracy |

±2% ES. |

±2% ES. |

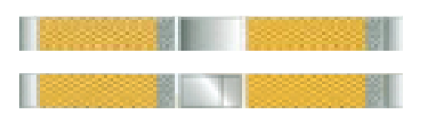

| Dimension of single brake test plate ( mm) |

1500X650 |

1200X750 |

| Separate distance between left and right plate recommended ( mm) |

900 |

900 |

| Test plate height by ground surface installation (mm) |

50 |

70 |

| Weight of brake test plate (kg) |

80 |

140 |

| Weight of sideslip test plate (kg) |

50 |

70 |

| Operation temperature(°C) |

5-40

|

| Operation humidity |

<95% no condense

|

U3 Console Specification

U3 console body

Embedded computer+ keyboard+mouse

Signal process unit

17inch CRT screen

Inkjet A4 printer

Power supply: 220VAC 50Hz 1 kW

Dimension: 1200X560X450 mm

Function And Interface

With Windows based software, all test procedures will be carried out automatically. There is a database to let customer easy to trace back and search test results.

Running on Windows

Vehicle information registration

Brake force curves

Sideslip value

Suspension curves

Self diagnostic

Self zeroing

Mal-function sensors indication

Intelligent calibration

Inertial center movement simulating display

Summary report and curve report output

Test database

RS-232 and Ethernet ports

English version software and other language available

Alternative

Model: L

With LED console, display will be on LED instead of CRT and a micro-printer integrated.

Product detail pictures:

Related Product Guide:

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Factory Free sample Chassis Dyno Testing - Platform brake tester – Orient, The product will supply to all over the world, such as: USA, Burundi, Juventus, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!