-

loaded mode

loaded mode

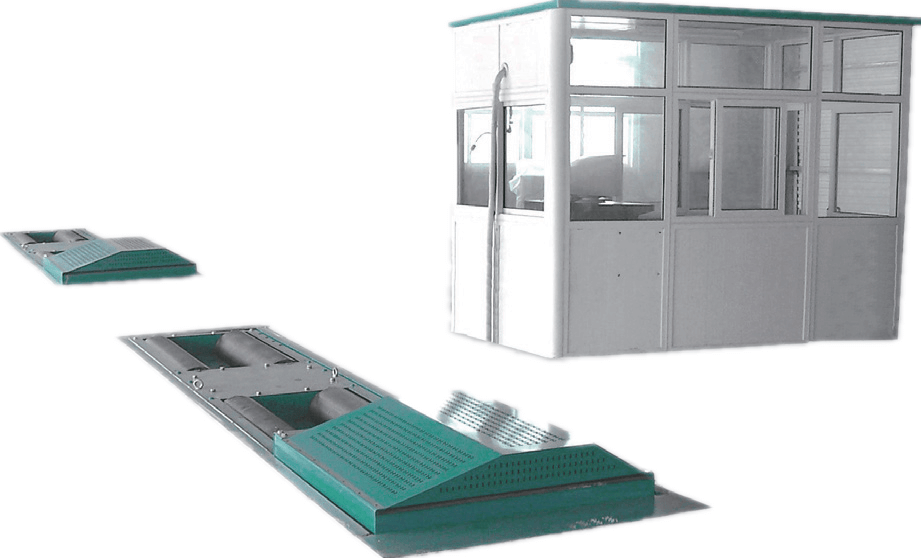

Loaded mode emission test system

Model:PROASM-9000® series

With loaded mode, PROASM-9000® performs vehicle emission test for diesel andgasoline engines.

PROASM900O® system meets BAR97 requirements and integrated with chassisdynamometer, gas analyzer, smoke meter, computer and other accessories.

With selection of system confin by customer themselves, they can useROASM9000® to test diesel one vehicle emissions or both in loaded.

PROASM900O® system awards National Gold Award of Innovation of EnvironmentProtection in China.

Main Testing Variables

OASM9000® tests vehicle emissions according to one testing mode or severalcombinations below thanks to up-to-date technology.

To test gasoline engine emission by procedures

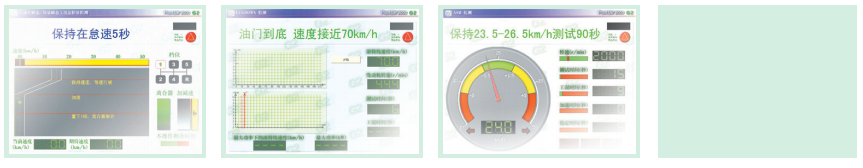

ASM (Acceleration simulation mode)

IG195

TSI (wo speeds idle)

To test diesel engine emission by procedures

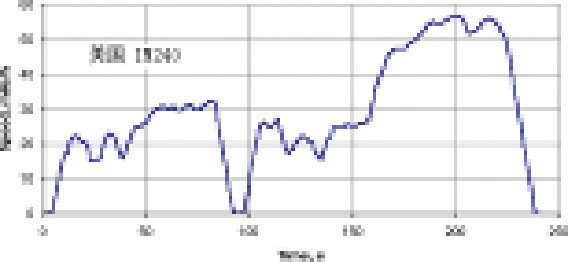

Lugdown

FA(Free acceleration)

All functions selected would be implemented by selection of differentsub-assemblies. accessories and software modules

Funtion And Interface

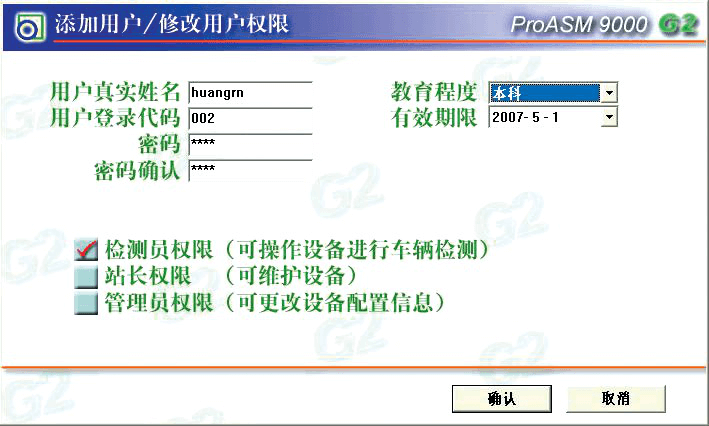

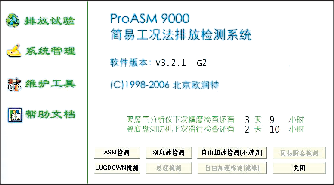

Software Version G2, based on our team s experience over10 years, shows a great function of security, easymaintenance, friendly interface, compatibility, selfdiagnostics, etc.

The testing functions include testing procedure, selfdiagnostic procedure, dada management procedure andLAN function etc.

The functions can be initiated in despite of whatcombination of hardware selected by user. The controllingand management of a emission testing system can be doneafter setup easily.

The friendly interface makes operating easily.

All operation of calibration, audit and leakage are prompted

Operating in case of any failure happens can be solved andleaded by PC

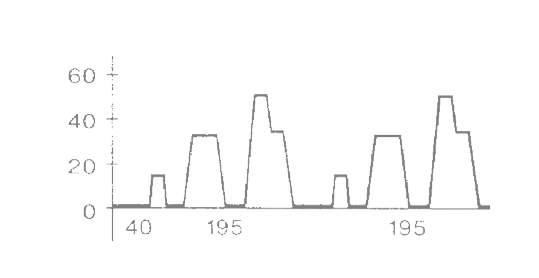

The results are display in digit and curve as well.

Multi-language version available

Remote Management

Ability of communicate with a citysVehicle Emission control andManagement System or VID.

It is possible to monitor testing procedureby authority through internet. (optional).

All monitoring requirements can beimplemented by on-line module.

Auto Maintenance

Checking the HC residence and starting thepiping cleaning automatically.

Checking zero gas automatically(optional).

Zeroing sensors and checking sensorsstatus periodically.

Cleaning the piping every time before shutdown.

Warming up automatically

Chassis Dynamometer

| Parameter |

Middle duty |

Heavy duty |

Twin axle |

| Model |

Ca-Dyno |

Me-Dyno |

Mh-Dyno/T |

| Axle load |

3,000 |

10,000 |

10,000 |

| Roller diameter (mm) |

217 |

217 |

420 |

| Roller spacing (mm) |

436 |

436 |

670/1350 |

| Min. Track length (mm) |

760 |

750 |

780 |

| Max. Track length (mm) |

2540 |

2710 |

2740 |

| Max Power absorbed (KW) |

140-180 |

270-330 |

2X350 |

| Max. Torque absorbed (Nm) |

1750 |

3300 |

2X3300 |

| Motor Power (KW) |

5.5 |

7.5 |

15 |

| Base inertia (kg) |

908 |

908 |

1460 |

| Speed test range (km/h) |

120 |

||

| Speed test accuracy (km/h) |

±0.2 |

||

| Torque test accuracy |

2% |

||

| Drive |

PWM+GBT |

||

| Port |

RS232C |

||

| Dimision L×W×H(mm) |

3980X700X370 |

4300X1410X550 |

4800X2650X550 |

Gas Analvzer

|

Gas |

Measuring Range |

Resolution |

Accuracy |

|

HC |

0-2000X10-6 |

1X10-6 |

±4X10-6 abs or ±3% |

|

CO |

0.00-10% |

0.01% |

±0.02% abs or ±3% |

|

CO2 |

0.00-16% |

0.01% |

±0.3% abs or ±3% |

|

NO |

0-4000×10-6 |

1×10-6 |

±25X10-6 abs or ±4% |

|

O2 |

0.00-25% |

0.01% |

±1% or ±3% |

Gas Analvzer

| Parameter |

Data |

| Measuring range |

N, 0~99.9% K,0~15/m |

| Resolution |

N, 0.1% K,0.01/m |

| Accuracy |

±2% |

| Stability |

±1%h |

| Working environment |

Temp. 5~40℃ Humidity 0~90% Baro 86~106kPa |

| Power supply |

AC220V±10%, 50Hz ±1% |

| Output |

RS232C (baud rate 1200,2400,4800,9600,19200) |

| Weight |

~13kg |

Console

| U3 console body, corrosion free surface by powder spray. | |

| Computer system | Industrial PC, Plll 1GHZ or more, 128M memory, 40G hard driver, 10/100MEthemet Port. 17 color fat CRI. Laserjet A4. |

| Communication Protocol | TCP / IP |

| Optional | Tamper recognizing device |

| Power supply | 220VAC 50HZ 2KW |

| Air pressure | 10.6-0.9 MPa |

| Operation temperature | 5-40°C |

| Operation humidity | < = 90 % ( No condense ) |

| Dimension | 900X600X1050 mm |

Safety And Security

No possibility to use any other softwareunless permitted.

All data are saved with MD5 encoded toprevent illegal change.

Protection of un-allowed operations such as,the un-enough sampling length into the tailpipe, un-authorized operator, un-satisfiedcircumstance. etc.

All events will be logged.

Weather Station

| Parameter |

Measuring Range |

Accuracy |

| Temperature (°C) |

-25 -+85 |

±1.5 |

| Humidity (RH) |

5%-99% |

±3.0% |

| Air pressure (kpa) |

50-110 |

±3% |